Why Must Medical Devices and Surgical Tools Be Marked?

To ensure the safety and efficiency of medical procedures, medical devices and surgical tools must be accurately marked. This practice aids in proper device management, ensures compliance with health regulations, and safeguards patient care. By adopting an effective labeling system, healthcare providers can significantly mitigate these risks, ensuring that devices are easily traceable, procedures are conducted safely, and regulatory mandates are met.

Key Challenges in Marking Medical Devices and Tools

HeatSign provides tailored solutions to meet regulatory requirements and enhance operational efficiency in medical device marking.

Strict Regulatory Compliance:

Challenge: Navigating FDA and international standards can be complex.

Solution: Our laser marking machines ensure compliance with UDI regulations, featuring advanced software for easy updates as standards evolve.

Material Sensitivity:

Challenge: Marking heat-sensitive materials without damage is critical.

Solution: Low-impact laser technologies minimize heat exposure, preserving the integrity of delicate materials.

Precision and Quality:

Challenge: Markings must remain legible through sterilization.

Solution: Our fiber and UV laser systems produce durable, high-contrast markings that withstand wear and sterilization.

Contamination Risk:

Challenge: Maintaining sterility during marking is essential.

Solution: Non-contact laser marking eliminates direct contact, reducing contamination risks.

Efficiency Demands:

Challenge: High-volume production needs to be met without sacrificing quality.

Solution: Our systems are optimized for high-speed operations, capable of marking multiple devices simultaneously.

Device Variability:

Challenge: Accommodating various device sizes and shapes can complicate marking.

Solution: Versatile machines with customizable fixtures allow for easy adjustments, ensuring precise marking for all device geometries.

Recommended Machines for Laser Marking Medical Instruments and Devices

Fiber Laser Engraving Medical Devices Machine

The HS-FLseries is engineered for high-speed, high-precision marking on metals and certain plastics. This machine is ideal for applications requiring permanent markings that withstand harsh conditions.

Key Features:

- Output Power: Available in 20W, 30W, and 50W options.

- Marking Area: Up to 110mm x 110mm, customizable based on requirements.

- Marking Speed: Achieves speeds of up to 9000 mm/s.

- Durability: Designed for continuous operation with minimal maintenance.

UV Laser Engraving Medical Devices Machine

HeatSign’s UV laser marking machines are designed for marking heat-sensitive materials like glass and plastics. They utilize advanced UV laser technology to provide high-quality markings without damaging the substrate.

Key Features:

- Output Power Options: Available in 3W, 5W, and 10W.

- Compact Design: Small footprint with modular design for easy integration.

- High Precision: Capable of achieving intricate details with a short pulse width and high peak power.

- Operational Efficiency: Supports continuous workloads of up to 24 hours.

Applications of Medical Device Laser Marking

Marking and coding of medical devices: A laser marking machine is used to print important information on medical devices for accurate management and tracking. A study highlighted that using laser marking for device tracking could cut inventory discrepancies by as much as 25%.

Marking of pharmaceutical packaging: Laser marking machines are used on pharmaceutical packaging mainly to ensure the safety and reliability of pharmaceuticals. The DSCSA requires pharmaceutical packaging to have unique identifiers, such as serial numbers, to help trace drugs and combat counterfeiting.

Marking of medical materials: Lasers are used to mark medical steel, keeping devices rust-free and ensuring UDI markings remain visible for the device’s life. The FDA requires medical devices to have a Unique Device Identification (UDI) in formats readable by both humans and machines.

Counterfeit Mitigation: Laser marking technology is important for tracking and verifying products. This advanced method facilitates the reliable tracking and identification of items, serving as a powerful deterrent against the proliferation of counterfeit goods.

Enhancing productivity and accuracy: Laser marking technology can create detailed markings such as texts, designs, and QR codes. It meets the high precision standards of the medical device industry. This technology is fast and efficient. Beyond its superior speed, this method surpasses older technologies by minimizing material wastage and boosting overall operational efficiency and output. This makes laser marking a better choice for making medical products because it is efficient and effective.

Application Case Studies of Laser Marking Medical Devices

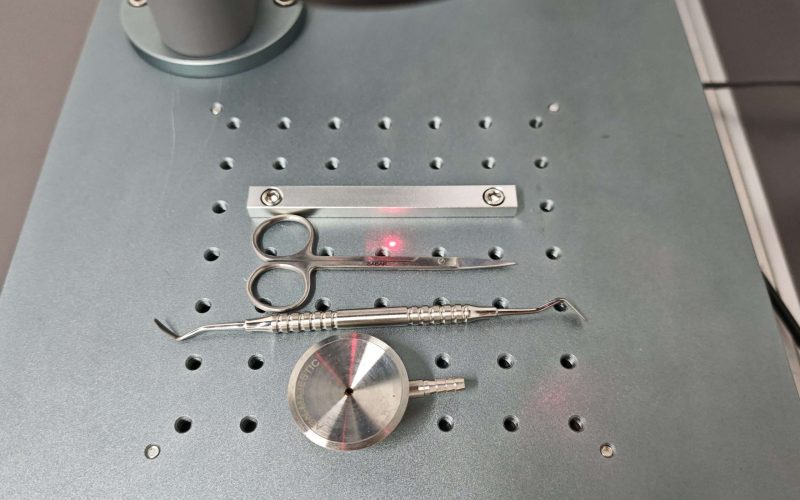

Laser Engraving Surgical Instruments

Application: Permanent marking of surgical scissors, forceps, and scalpels with unique identification numbers for traceability and compliance with health and safety standards.

Process: Fiber laser engravers are used due to their precision and ability to produce high-contrast marks without affecting the tool’s structural integrity. The laser precisely engraves small, readable texts and codes that withstand repeated sterilization processes.

Outcome: Enhanced traceability and inventory management of surgical tools within medical facilities, ensuring tools are easily identifiable and reducing the risk of misplacement or mix-ups during critical surgical procedures.

Orthopedic Implants

Application: Marking of titanium hip and knee replacements with batch numbers, sizes, and manufacturer information.

Process: UV laser marking machines are preferred for their gentle marking capability, crucial for maintaining the biocompatibility and structural integrity of the implants. These machines provide precise, indelible markings that are essential for traceability and patient safety without compromising the material.

Outcome: Reliable identification of orthopedic implants, facilitating better post-operative tracking and management. This also aids in recall processes and enhances the quality control measures of implant manufacturers.

Dental Instruments

Application: Engraving dental drill bits and other small instruments with serial numbers and manufacturer logos.

Process: Fiber laser marking systems are utilized for their ability to achieve detailed, fine markings on small, intricate devices. They can mark hard-to-reach areas and complex shapes, essential for the diverse range of dental instruments.

Outcome: Improved inventory and sterilization process management within dental practices. Markings help in the quick identification of specific tools, contributing to operational efficiency and patient safety by ensuring the correct and sterile instrument is used for each procedure.

Why Choose HeatSign for Medical Device Laser Marking?

✔ 15+ years of industrial laser marking experience

✔ Full support for UDI-compliant marking

✔ CE/FDA-certified systems

✔ Fast delivery and global logistics support

✔ Free sample testing and pre-sales consultation

✔ Customization for all device sizes and marking needs

Conclusion

Laser markers offer amazing marking solutions for different medical devices. There are many types of laser markers with different engraving capabilities. Choosing the most appropriate marking solution for your project is important as it will help save time and money. Are you looking for where to get laser markers for your medical devices? Contact us today to get the value of your money.

Testimonials

We specialize on medical and surgical tools production and have tried this offer in our company. What to say, it is really useful. The process of marking has become easier several times.

Frequently Asked Questions

Is laser marking safe for medical devices?

Yes, laser marking is a safe process that does not introduce harmful substances into medical devices. The markings are corrosion-resistant and can withstand sterilization processes without compromising the integrity of the device.

How long do laser markings last?

Laser markings are permanent and designed to withstand harsh conditions, including cleaning agents and sterilization processes. They will not wear off unless the material itself is removed or damaged.

What types of lasers are best for medical device marking?

For medical applications, UV lasers are ideal for heat-sensitive materials, while fiber lasers are commonly used for metals. The choice of laser depends on the material being marked and the specific requirements of the application.