What is Permanent Marking on Metal?

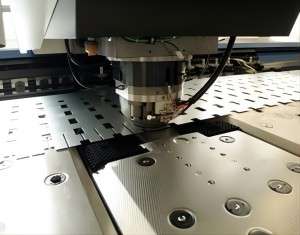

Permanent marking on metal involves techniques that alter the surface to create marks that remain legible throughout the product’s lifespan. Essential in industries like automotive, aerospace, and medical devices, these markings ensure traceability, product branding, and regulatory compliance. By implementing robust permanent marking solutions, companies can avoid issues like product recalls due to unclear markings, protecting brand reputation and ensuring compliance.